LASER SYSTEMS FOR CERAMIC, CRYSTAL, AND GLASS ETCHING

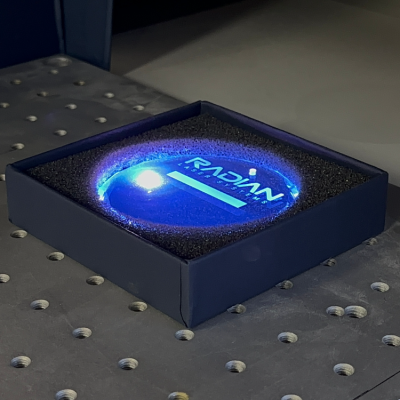

Laser etching and engraving glass is a fine art. Radian Laser Systems’ lasers are designed to mark delicate items like glass without compromising the integrity of the workpiece. Radian’s UV systems are well-suited for ceramic, crystal, and glass etching and engraving. Some everyday glass items marked with our systems are mugs, glasses, vases, awards, jewelry, and more.

Laser Engrave on Curved Crystal and Glass Surfaces with Our 3D Technology

Our galvo-based UV laser engraving systems have access to a 3D plane, allowing them to better engrave on curved surfaces like drinkware and other asymmetrical objects.

Our 3D technology at Radian Laser Systems is unique because you can mark on a curve without rotation of the workpiece. Combine your glass and acrylic laser engraver with our optional Drinkware Rotary Kit to enhance production and provide increased customization for customers.

Get the Best in Class with Our UV Laser Systems

Radian’s galvo-based UV systems use mirror-based galvanometers to direct an ultraviolet (UV) laser beam for marking and engraving with precision. This technology is significantly faster than traditional gantry systems because it moves the beam with small mirrors instead of a heavy laser head or workpiece. The result: greater productivity, lower labor costs, and more profitability for your business.

Why Use Our Laser Systems for Etching Crystal and Glass?

- 3D Engraving: Radian Laser Systems has a third axis that changes the focus and allows for engraving on curved surfaces.

- High Speed: UV lasers are 3 to 5 times faster than traditional methods of glass marking!

- Versatility: Laser engrave crystal, glass, acrylic, and more with these machines.

- Precision: Our UV systems can produce an ultra-smooth and contrasting mark that rivals the results typically achieved with sandblasting.

- User-Friendly: Radian Laser Systems’ software is easy to use. We also offer in-person and virtual training to help you set up your laser. Need more support? Master etching crystal and glass on your laser machinery with our training videos!

- One-Year Warranty: All of our products at Radian Laser Systems come with a one-year warranty to protect your investment and provide peace of mind.

- Scalability: The hardware and software of each system can be customized to your exact needs.

Discover Faster and More Efficient Laser Solutions at Radian Laser Systems

Whether you’re etching crystal wine glasses or engraving glass or acrylic awards, Radian Laser Systems has the solutions and expertise you need to excel. Our advanced laser machinery is designed in-house for fast and precise glass engraving to ensure professional results every time. We also enable easy setup and use with our intuitive software and controls.

Radian Laser Systems provides accessible support at every stage. We’ll send out our expert technicians to help you install your acrylic laser engraver, teach you how to use your system, or deliver valuable support for our products. Request a quote!

FAQs

What laser machine is best for precision glass engraving?

UV lasers are best for precision crystal and glass etching. These systems use a short wavelength that breaks down material bonds without generating too much heat, making them ideal for intricate designs on glass.

Can I use your machinery for crystal wine glass engraving?

Yes! You can laser engrave crystal, glass, and acrylic with our machinery at Radian Laser Systems. Our user-friendly software makes it easy to set up your laser parameters, including speed, power, and frequency. This allows you to create ultra-precise and smooth marks without compromising the fast processing speeds you need to boost productivity.

Another key benefit of our galvo-based UV machinery at Radian Laser Systems is its 3D capabilities. These lasers have access to a 3D plane, allowing for better laser etching on crystal wine glasses and other drinkware.

What kind of laser do I need to mark acrylic?

A CO2 laser is an excellent choice for acrylic laser etching because the material effectively absorbs the laser beam. The absorption means that, once the light hits the acrylic surface, the target immediately vaporizes. This leaves behind a clean mark.

It’s best to choose an acrylic laser engraver with 3-axis control rather than one with a standard XY plane. These machines move around curves for even engraving. This offers more flexibility and precision for acrylic parts with different heights, depths, and contours.

SUGGESTED LASER SYSTEMS FOR GLASS & CRYSTAL

CERAMIC, GLASS & CRYSTAL ENGRAVING EXAMPLES